The latest News, the fastest to know

News Details

The characteristics of Anlai light-transmitting panels.

Release time:

2019-11-21

In lighting panels, the types, quality, and proportions of resin and fiber have a significant impact on their performance.

Anai lighting panels select different grades of glass fiber and resin, adjusting the proportions of both can greatly change the optical and physical-mechanical properties of the lighting panels. Generally speaking, composite materials made with glass cloth have higher strength, being 1 to 2 times stronger than lighting panels made with glass fiber felt. Using heat-resistant transparent resin can increase the operating temperature of Anai lighting panels to over 100°C, and using flame-retardant resin can enhance the fire resistance of Anai lighting panels to achieve a self-extinguishing effect.

The superior performance of Anai lighting panels is mainly reflected in the following points.

(1) Excellent impact resistance. The impact toughness of Anai lighting panels is significantly better than that of traditional glass lighting materials. They are resistant to hail and collisions and will not experience the self-explosion phenomenon caused by temperature changes like glass. Therefore, using Anai lighting panels is safer than using glass for lighting. Anai lighting is suitable for lighting projects where glass cannot perform, such as skylights in industrial plants, lighting in factories that produce flammable and explosive sparks, and lighting in agricultural and fishery greenhouses that are prone to hail damage and rapid temperature changes.

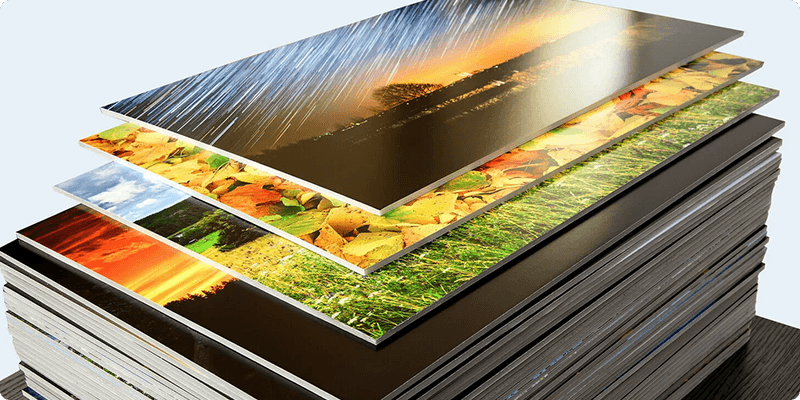

(2) The light transmittance of Anai lighting panels can reach 85%, and can be as high as 90%, similar to that of glass. However, they have sufficient strength and rigidity, combining the characteristics of both lighting and structural materials. They are multifunctional materials that can transmit light while bearing structural loads. Replacing glass with them can simplify design and reduce the structural materials (window frames, sashes, etc.) needed for lighting projects, greatly improving lighting effects and reducing project costs.

(3) Low thermal conductivity. The thermal conductivity of glass is 1.392W/(m.k), while that of Anai lighting panels is only 0.232W/(m.k), more than 5 times lower than that of glass. Therefore, designing factory and housing lighting with Anai lighting panels can effectively save energy, whether for winter heating in cold regions or summer cooling in southern regions.

(4) Uniform light transmission. Anai lighting panels can be made into non-homogeneous materials, causing light to scatter as it passes through, resulting in uniform indoor lighting without spots or glare, making them particularly suitable for precision processing workshops, sports venues, and shopping malls.

(5) Lightweight and high strength. The relative density of the light-transmitting composite material is 1.5 to 1.9, about 60% to 70% of the relative density of glass. Therefore, the weight of the composite lighting panel per square meter is only about 20% of that of glass, and the tensile and bending strength of Anai lighting panels is 1 to 8 times higher than that of glass. Thus, using Anai lighting panels can significantly reduce the self-weight of lighting products, increase the size of lighting components, improve installation efficiency, and lower project costs.

(6) Excellent performance designability. The greatest advantage of Anai lighting panels is that their physical and mechanical properties can be designed according to usage conditions, such as strength design, light transmittance and quality design, heat resistance and fire resistance design, etc. They can also be colored according to decorative project requirements, making the products vibrant and beneficial for lighting projects in municipal construction.

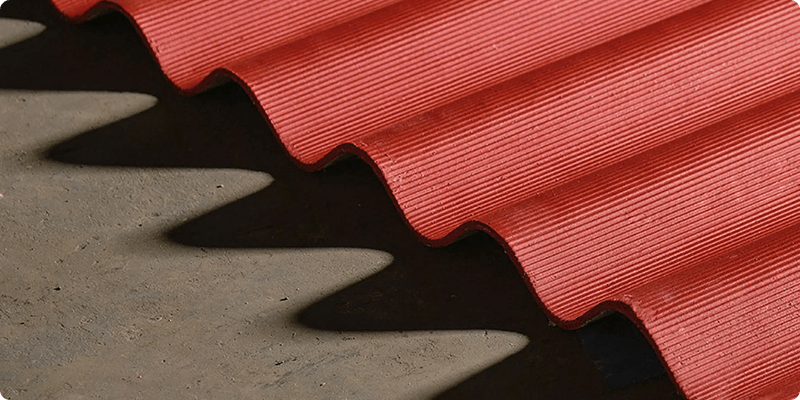

(7) Easy to mold. In addition to various wave-shaped panels, complex large-sized lighting products can be manufactured in one go, which is extremely beneficial for facilitating construction and reducing project costs.

(8) Convenient for construction and transportation. Anai lighting panel products are lightweight and have high impact toughness, which prevents damage during construction and transportation, while general glass can be damaged about 5% during these processes. Using Anai lighting panels can reduce losses and lower project costs.

(9) Good durability. Generally, unprotected lighting panel products will have reduced strength and light transmittance after 3 to 4 years of use, but Anai lighting panels undergo anti-aging treatment, allowing their lifespan to reach over 20 years, with light transmittance still around 70% even after 20 years.

(10) The transparency of lighting panels is relatively low (transparency is different from light transmittance), with a maximum of 90%, which is much lower than the 99% transparency of glass. Generally speaking, low transparency is a disadvantage, but it can also be an advantage. When used in lighting design for industrial or public buildings, low transparency can be beneficial as it allows for uniform lighting without spots.

Previous article

Related News