Committed to providing professional FRP lighting board/PVC foam board production services

About Us

About Flamtechnetium

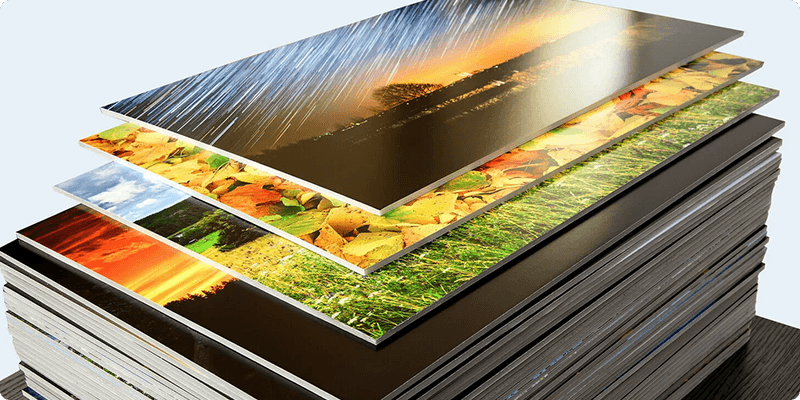

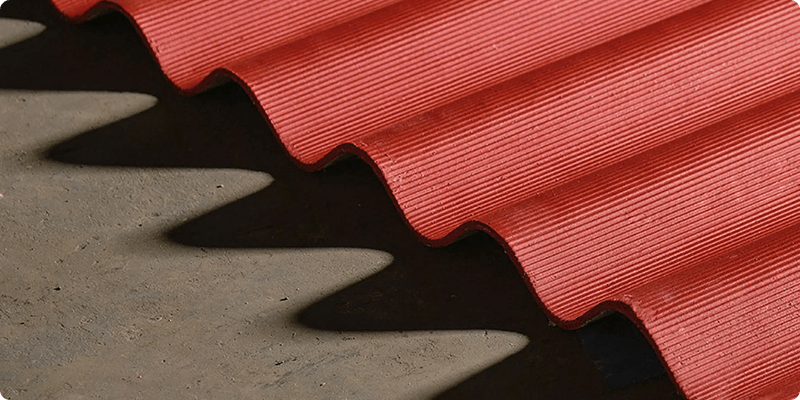

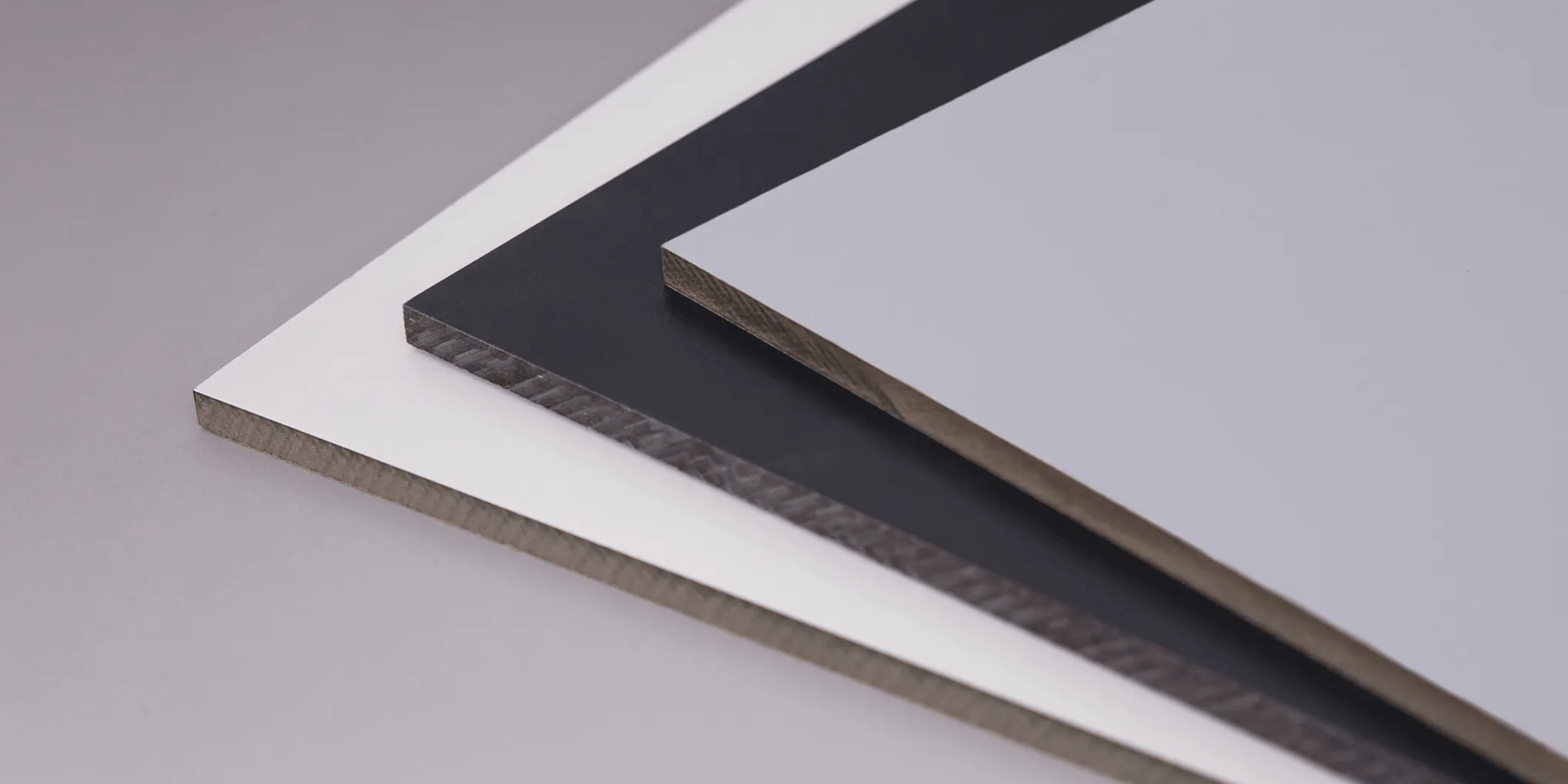

Hangzhou Friend Industrial CO., LTD. was established in May 2013, covering an area of more than 20000 square meters, with modern standard production plants and domestic advanced automated production and testing equipment. The company is located in Hangzhou, Zhejiang Province, China, which is known as "paradise on earth". It is a modern high-tech enterprise with high-quality supply chain integrating R & D, procurement, production and sales. The company mainly produces PVC foam board with "synthetic wood", also known as Chevy board, Andy board and foam PVC board. The product specifications are complete, the quality is stable and reliable, and the technical indicators are advanced. Since the company's products were put on the market, with its high quality and low price characteristics, it has won the favor of customers and is well received by new and old customers. The products sell well all over the country and are exported to the United States, Britain, Germany, France, Russia, Japan, India, Southeast Asia and other dozens of countries. The company attaches importance to scientific management, continuously strengthens product technology innovation, improves product quality and variety diversification, and ensures product production standardization and quality stability. Companies with strong strength, high-quality supply chain management level, advanced production technology, professional scientific research and technical personnel, dedicated to provide customers with quality products and services. The company through the implementation of talent war road, science and technology strategy, innovation strategy, brand strategy, with a new attitude to meet the international competition.

Has been established for 12 years

Covering an area of more than 20000 square meters

Cumulative Service 1000 + Enterprise

Enterprise advantage

Powerful

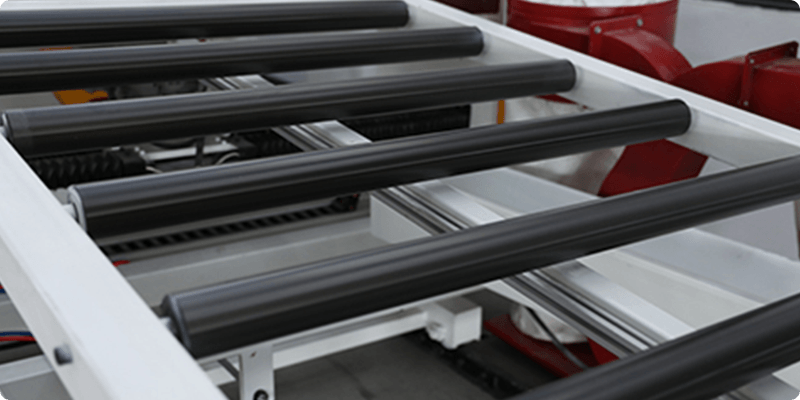

Since its establishment, Fulan Technetium Industry has served 1000 enterprises. It has its own 200000 square meter production base, 10 fully automated production equipment and 10 production lines. The average annual production capacity of white pvc boards is over 30000 tons. It has independent research and development and design, complete product categories and stable and guaranteed supply.

price concessions

The direct selling mode is implemented to directly target the end customers, eliminating the intermediate links and avoiding many problems. The research and development team has rich experience, and the research and development engineers have more than 10 years of in-line experience, and have successively developed a series of PVC products including PVC pallets and T-shaped clapboards. With more than 100 experienced technical workers and many backbone management experience, PVC plate manufacturers have successfully realized high-standard automatic production.

Quality Assurance

There are many production quality inspection processes. We choose brand suppliers for raw materials to ensure the adequacy and quality of the supply of goods. The production process is checked layer by layer, and each piece can only be delivered out of the warehouse after passing the inspection. The independent product inspection department, all products go through strict quality inspection and issue inspection reports before leaving the factory.

Intimate service

Set production and processing, distribution and storage, after-sales one-stop service: standard details to implement the contract, commitment to quality assurance, non-customized unconditional return and exchange; Self-built logistics team, with fleet delivery door-to-door service, tracking the whole process from order to delivery, on-time delivery, the customer team adopts shift service system, 24-hour online waiting to serve customers, and quickly respond to your service needs.