Committed to providing professional FRP lighting board/PVC foam board production services

About Us

About Anai Building Materials

Hangzhou Annai Building Materials Co., Ltd. was established in May 2003, specializing in providing high-end products for Chinese and foreign customers. The company mainly produces two categories of products, the first category of products is FRP lighting board, the second category of products is "synthetic wood" said PVC foam board.

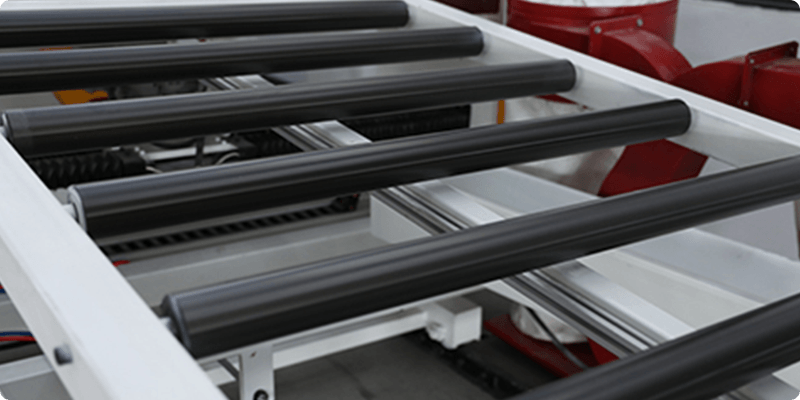

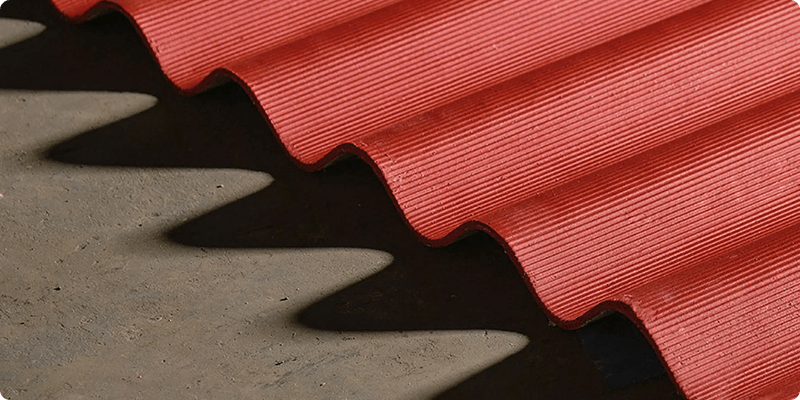

Anai Building Materials has modular flexible production line technology from Britain, with a total length of 72 meters, a height of 6 meters, a width of 2.5 meters, and a production capacity of up to 6000 meters/day. It has various composite functions such as film sticking, shoe coating, glass fiber felt, reinforcing ribs, bubble discharging, etc. It is one of the FRP assembly line production equipment with advanced technology, complete functional models and high degree of automation in China. It can produce various forms of plates with a thickness of 0.8 mm-2.5mm, a spread width of 300mm-1250mm, and any length, covering more than 100 types of plates in the current domestic light steel market.

The company integrates design, production, sales and service. It can independently design and produce various plate types according to customer requirements, and with its own excellent production process and coating technology, it can meet the different needs of customers. Products are widely used in various steel structure factory buildings, stadiums, storage supermarkets and other large public facilities. With the increasing market demand, the annual production capacity of more than 2 million meters.

Since the company's products were put on the market, with its high quality and low price characteristics, it has won the favor of customers and has been well received by customers. The products are sold in more than 20 provinces, cities and autonomous regions across the country, and the marketing network is all over the country.

In line with the purpose of providing high-quality services to customers, the company has continuously improved its own system and passed the ISO9001:2000 quality system certification in April 2004. At the same time, the product itself has also passed the Shanghai FRP/Composite Industry Testing Center, the National Chemical Building Materials Supervision and Testing Center and the National Fire Equipment Supervision and Testing Center. The company from raw materials into the factory to product molding, the whole process around the quality system operation, as always, to provide customers with high-quality products, perfect service.

The company's products cover five types: general-purpose, economical, heat-insulating, flame-retardant, and weather-resistant. According to different product types, it provides customers with "Ten-Year Quality Guarantee", "Fifteen-Year Quality Guarantee" and "Twenty Years" Quality Guarantee ".

In March 2006, the new plant and equipment with a total investment of 8 million was put into use, and the production strength was further strengthened. Taking this opportunity, the company will welcome guests from all directions with a new look and create a new world. "The road is invisible, and the walker has no borders." Today, with the integration of market economy, the company will focus on the future, continue to deepen reforms, and unremittingly pursue co-survival and development with customers, and inject new ideas into the development and growth of domestic FRP lighting panels. vitality.

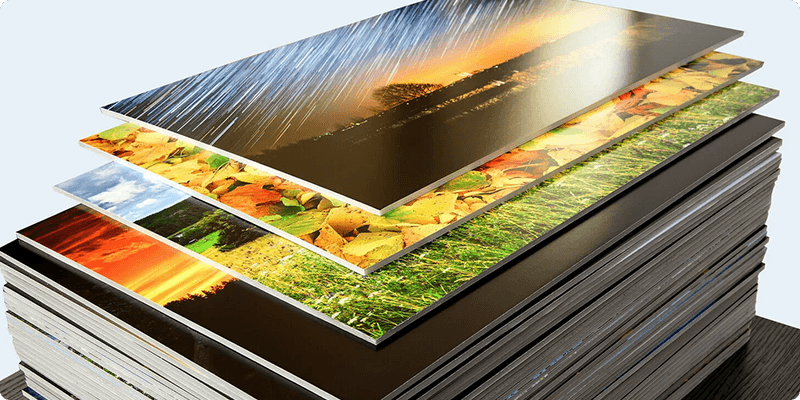

FRP is the abbreviation of English Fibreglass Reinforced Polyester. The full name is glass fiber reinforced polyester lighting board. It is a lighting board substitute composed of high-performance film, high-quality polyester and reinforced glass fiber. The company introduced the British advanced FRP plate automatic continuous production line technology, the use of domestic and foreign well-known manufacturers of high quality raw materials, the use of the United States imported DuPont 301 and Ganware-PT055 film, edge cutting with no water dust cutting technology.

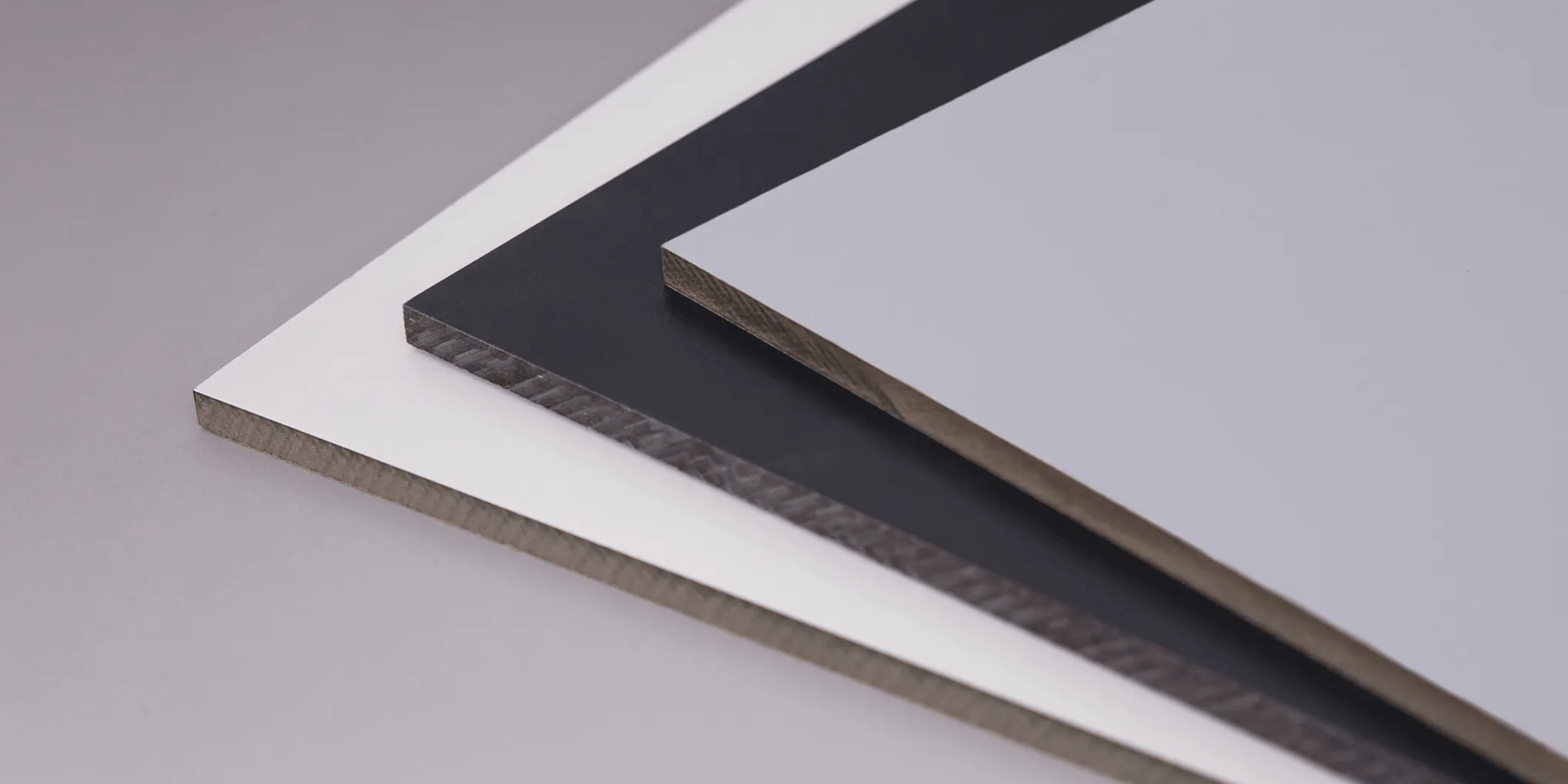

The full name of PVC foam board is Polyvinylchlorid Foam Board, also known as Chevy board and Andy board. It is a new type of chemical building material with uniform cell structure made of PVC (polyvinyl chloride) resin as the main raw material and chemical additives and micro-foaming extrusion production line. Its density, performance, appearance and texture are very close to natural wood. It is also called "synthetic wood". And waterproof, fireproof, mothproof, sound insulation and other properties are significantly better than natural wood.

Established for 22 years.

Production capacity up to 6000 m/day

Annual production capacity of more than 2 million meters